Shaft seal

2023-01-02

The great thing about everything is how much of it there is. If, for example, you need a shaft both sealed and wiped life has a solution. Why, you ask, would a middle aged man need a shaft both sealed and wiped? Well age is just a number and this middle aged man has a robust shaft that needs to be both sealed and wiped because that just happens to be his hobby. A boy and his shaft. It’s a tale of the ages.

Enough philosophy and psychiatry. Lets get down to shaft wiping.

As to all problems in life, McMaster has a solution:

https://www.mcmaster.com/1199N14/

For a very reasonably sized shaft of 25mm they offer a seal that will handily fit in a 35mm bore. These are all good numbers.

The shaft-adjacent problem we’re trying to solve is how to keep swarf out of needle bearings in a design that they do not belong in. Specifically an affordable pipe notcher displayed in situ below.

The issue here is as the tool cuts, it generates metal cuttings that will be prone to adhering to the sticky, greasy shaft holding the throbbing cutter. That will in turn convey the detritus into the messy hole formed by the needle bearings.

One solution would be to buy needle bearings with seals. The issue there is that needle bearing seals are designed for radial motion, not axial. Which makes sense since needle bearings are designed for radial motion. Here we’re abusing the needle bearings by making the shaft move both radially and axially – in and out and all about 🤭🤭🤭🤭🤭.

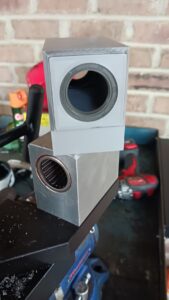

Despite the endless solutions to boundless shaft problems offered by Internet banner adds, Neal and I chose to experiment with our shaft in search of a new solution. This is what we came up with:

Here’s another view mounted onto it’s mate:

And the late-night full-penetration shot:

I have the hiccups and I’m going to bed.