Vic’s IO Board V1.0

The Why

It all started with a thermostat. As in I wanted a new one (See here). Because I am super special little snowflake, none of the thousands of thermostats on the market suited my needs. The initial inspiration is well documented; I will not waste time repeating myself.

So I needed a way for the control logic to interface with the physical world. This of course is done via an IO board and there seemed to be two options – the industrial-level stuff intended to be used with PLCs and the amateur “arduino”-level stuff that’s available everywhere on the internet for less than $20.

The cover for the first party is in the 5 digit range even if you manage to get an invitation. The other party is one guy with a funnel looking for someone with a keg. I wanted to be in the fancy party, but did not have the money nor the invitation to get in.

So I decided to put my experience gained through being a bartender at the fancy party into an IO board of my own. That’s enough analogy maceration.

My goal was to have a robust IO board for my personal project(s). I wanted the board to:

- work on 24VDC

- minimize the impact of human error by having protected inputs and outputs

- be a coherent package

- be as easy as possible to troubleshoot and integrate

- have some level of support by the manufacturer

Basically, I wanted a robust piece of gear and since I couldn’t afford one I made my own.

The What

The board, in its current V1.0 incarnation satisfies most of my requirements. Only thing lacking is support from the manufacturer. It’s a hassle. They’re real moody pricks.

Board features and specs:

- Dual micro-controllers

- Dedicated communications processor

- Dedicated input/output processor

- 24VDC power supply

- Fused

- Reverse polarity protected

- Over-voltage protected via crowbar circuit

- ESD protected

- Analog sensor power supply

- Over-current protected with software detect and reset

- Diode-protected output

- Eight analog inputs

- Over/under voltage protected

- 12-bit resolution

- Four ICTD inputs that can double as 0-500mV inputs

- Four 4-20mA inputs that double as 0-5VDC inputs

- Adjustable low-pass filter on the analog inputs

- Four digital outputs

- Over-current protected with software detect and reset

- Sourcing configuration

- Diode-protected output

- Communications

- RS-232 signaling

- Hardware (CTS/RTS) flow control

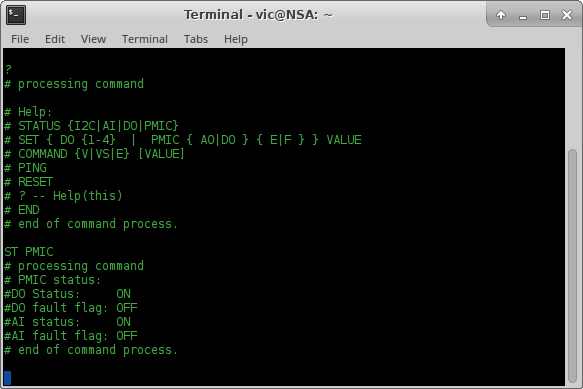

- Text-based interface intended for human use

- Binary interface intended for machine use

- Firmware

- Mostly C code written with explicit goal of not being unnecessarily clever and hard to understand

- Minimal assembler. Some assembly is present on the account that it is unavoidable and C inline assembler is ugly.

- Thoroughly documented

- No external dependencies

- Open design

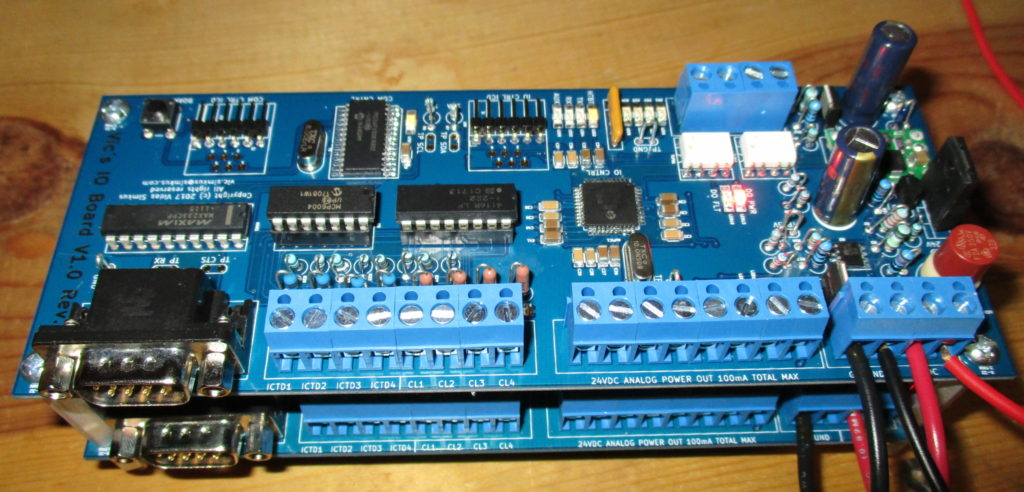

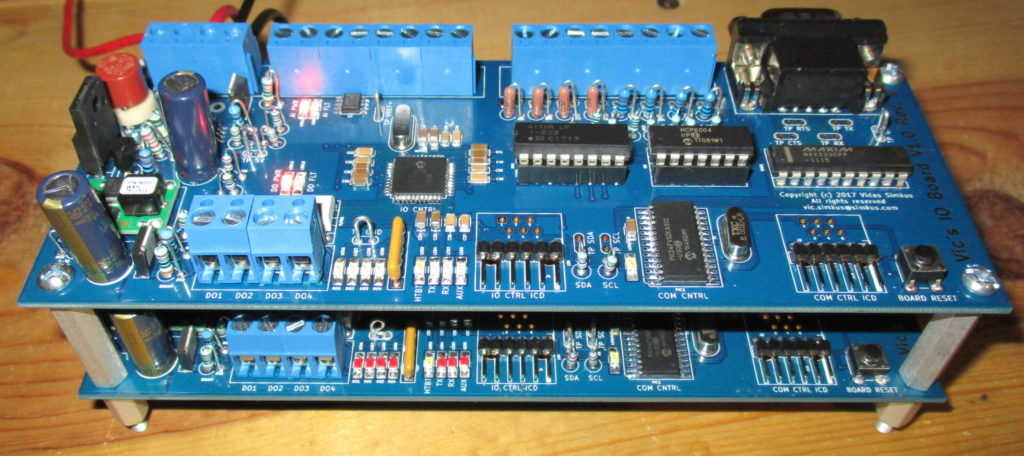

Bellow is a few pictures in the dual board configuration. Why dual board and not two, three, or four? Simple. Because I am the decider and I decided.

Click on the pictures to expand them.

Top view

Another top view

Dual stack – digital output terminals

Dual stack – RS-232, analog input, analog power supply, and power supply terminals

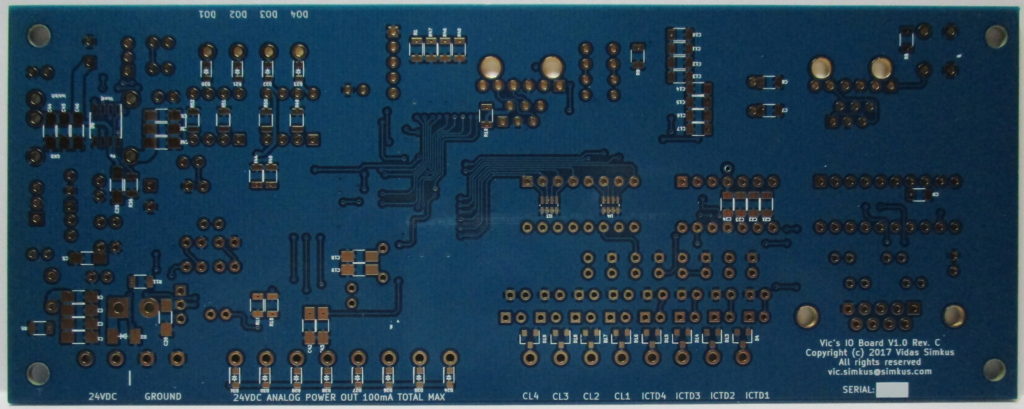

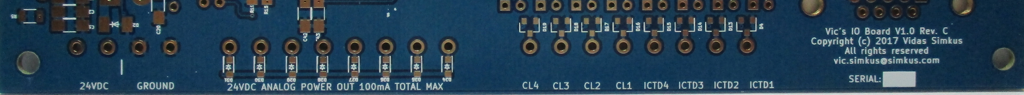

Back of the PCB

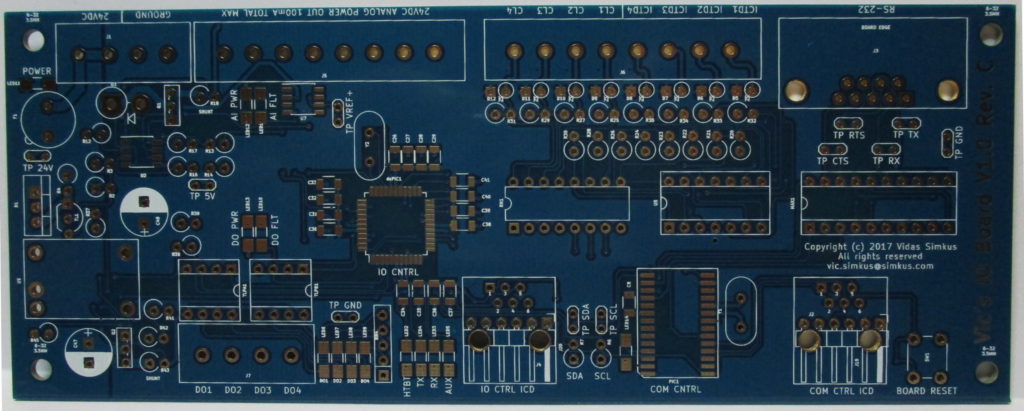

Front of the PCB

Text-based interface intended for testing/human use