2017-06-03

2017-06-03

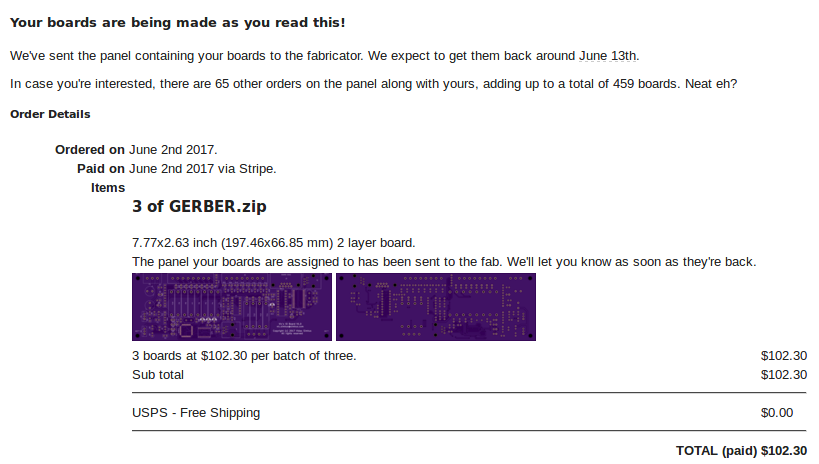

The board has been ordered, panelized, and sent off to production. So far the process has been moving along at a much faster clip than I anticipated. The board was panelized the same day I placed the order even though I ordered fairly late in the afternoon; certainly after business hours. The next day I received an email that the board has been sent off to fabrication. I know the email says that they expect the board back by June 13th, but at the rate the process is moving along I wouldn’t be surprised to have the board in my hands by end of next week. We’ll see I guess.

This has been a very educational experience so far and I’m certainly looking forward to version 2.0 of the board. For V2.0, I’m currently tossing around the following revisions:

- Use R485 rather than the current RS232. This would allow me to daisy chain boards without requiring extra ports on the controlling microprocessor. This would also allow me to get rid of the DB9 connector which would reduce the board area thus reducing the cost.

- Replace all of the analog output fuses with some sort of integrated overload protection. The GEA/FES boards seem to use a single IC of some sorts, but I’ll have to bring my loupe to work to get markings off of it. As with getting rid of the DB9 connector, getting rid of all those fuses would result in a smaller board.

- Add PWM output. That coupled with a PID algorithm implementation will allow me to control the electric heater in the air handler with a finer granularity than on/off.

- Make analog inputs field-configurable. Right now I have four ICTD inputs and four 4-20mA loop inputs. The only differences are the terminating resistor values and the fact that ICTD inputs get fed into an opamp. Right now I’m thinking that I wouldn’t even need the opamps if I fed the signal into a “real” 16+ bit ADC. Need to do more research on this.

The next step is building a shield for the BBB to break out RS232 interfaces at proper signal levels and power control. I’m very much looking forward to that step. The selection of BBB shields seems to be fairly anemic. I wonder if that’s due to their target audience making their own shields rather than relying on pre-made stuff like the Raspberry PI community.