Reduce, Reuse, Repair

2023-03-18

We talk about how wasteful the throw-away culture is. The modern trend of our stuff being hostile to repair is certainly a topic of conversation amongst some societal circles. Idea being that it is preferable for a thing to be designed in such a way as to be repairable rather than a thing to be designed in such a way as to be non-repairable. A non-repairable thing would obviously have to be discarded in case of malfunction and a whole new thing purchased.

If a thing could be repaired for 10%, 90% of the thing is reused. This seems preferential if you already have the 90%, but is not if you’re the entity who stands to benefit by selling you the 100% rather than 10%. From their point of view it makes complete logical sense to prefer that you buy 100% rather than 10%. Math is beautiful.

And through this push and pull, the ebb and flow, the yin and yang, we continue to eat, drink, and fuck.

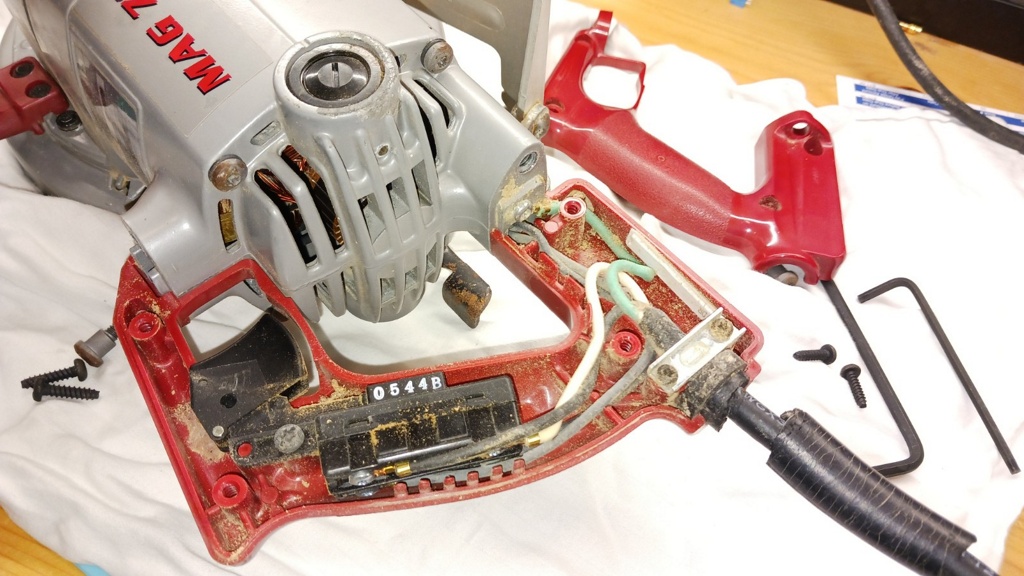

This is the cord of my most favorite saw, A Skill HD77M, I bought the thing easy two decades ago.

This is considered a “professional” tool and as such repair parts are available. eBay sent us some parts merely in exchange for money. They’re true friends.

But wait, why are these fancy BOSCH parts? BOSCH from Germany?! The same! Hencho en China.

To me that is testament to human ingenuity. Every single detail had to be accounted for in the design. Plastic handles don’t grow in the ocean, you have to make a mold, inject the plastic, etc. That then has to be mated to a metal casing that is made by die casting. Die casting is injecting molten metal into a mold under pressure. Think about that – we melt metal and pump it around like a liquid. Metal. And this it is done under industrial scale. Meaning repeatably, over and over and over and over again at 90+% success rate. It’s fucking insane.

Here we are with a replacement cord and dingus guard.

And all back together. Great success.

Now for example if the handle was say glued together rather than screwed together or if the cord and dingus guard was not available, well then you’re faces with less preferential choices. Work with a half-ass damaged tool? Jury rig something together? Toss the tool?

But wait, there is more. I got curious as to why I ordered Skill parts but got BOSH parts. Well in the 90s BOSH bought Skill. Skill, an American company, a company that created a genre of products, not just a singular product; a company that created a physical thing out of an idea and that invented a way to realize that idea on an industrial scale, was acquired by a German company. A few decades after we were killing them en masse, we sold the Germans our premier tool used in the building of our homes.

But wait, there is more. In 2016, BOSH sold Skill to some Chinese company you’ve never heard of – Chervon. Not Chevron – Chervon. They are lead by Peter Pan. You cannot make this shit up. A company appears out of the Communist apparatus of China, our adversary on the global stage, buys up the worlds tool manufacturing capacity, and no one says anything. In other words, Communist China has in their capacity to bring global power tool production to a halt. This is a bad thing.

But wait, there is more. The skill saw was invented in New Orleans! In the 1920, some cat strapped a motor to a blade after he saw a sugar cane harvest. The fact that you needed a generator to drive the saw made it useless for cane harvest so he moved the operation to Chicago and the rest is history. All that Louisiana-inspired knowledge and ingenuity are now property of the Communist party of China.