fancy schmancy formula

2023-06-21

From the previous post we know that we can assume that \(K = 1\) so Euler’s critical load formula simplifies to

$$ P_{cr} = \frac{\pi^2EI}{L^2} $$

The modulus of elasticity for our material is 30,000ksi which is a fancy schmancy way of saying 30,000,000 psi. So \(E = 30,000,000\) and the formula gets even simpler. The magic is slowly melting away.

$$ P_{cr} = \frac{\pi^230,000,000I}{L^2} $$

\(pi\) is \(pi\). We know it’s delicious and every calculator has a \(pi\) button on it so it’s not a mystery. \(L\) is the length of the column and by using our tape measure we know that it’s 88 inches. \(88^2=7784\) so our formula gets even less magical.

$$ P_{cr} = \frac{\pi^230,000,000I}{7784} $$

\(I\) is the second moment of area of the cross section of the column. Second moment of area is essentially how much stuff and how far that stuff in an object is distributed from some axis. That’s why I-beams are shaped the way they’re shaped. The bulk of the material is placed as far away from the bending axis as is practical. In my mind it’s kind of like a lever. The longer the lever the more force it can exert. While I respect calculus, I also consider grinding it out kind of like making your own wrenches. If that’s your hobby – great. If it’s not then your time is better spent letting someone else do it. To that end, Wikipedia provides us with a list equations for second moment’s of area for common shapes. Since we’re using a pipe, the equation for an annulus is of interest to us.

$$I_x = \frac{\pi}{4} (r_2^4 – r_1^4)$$

Where \(r_1\) is the inner radius and \(r_2\) is the outer radius. Since we’re using standard materials we lookup the values in the pipe schedule for NPS pipe. Now since it was conjured up by humans, “pipe size” has nothing to do with actual pipe size. I guess women really mean it when they say that size doesn’t matter.

| Pipe size, nominal (in) | OD, actual (in) | Wall thiccness (in) | \(r_1\) | \(r_2\) |

| 1.5 | 1.900 | 0.145 | \(1,900/2-0.145=0.8050\) | \(1.900/2=0.9500\) |

| 2.0 | 2.375 | 0.154 | \(2.375/2-0.154=1.0335\) | \(2.375/2=1.1875\) |

| 2.5 | 2.875 | 0.203 | \(2.875/2-0.203=1.2345\) | \(2.875/2=1.4375\) |

| 3,0 | 3.500 | 0.216 | \(3.500/2-0.216=1.5340\) | \(3.500/2=1.7500\) |

| 3.5 | 4.00 | 0.226 | \(4.000/2-0.226=1.7740\) | \(4.000/2=2.0000\) |

On to second moments of area then

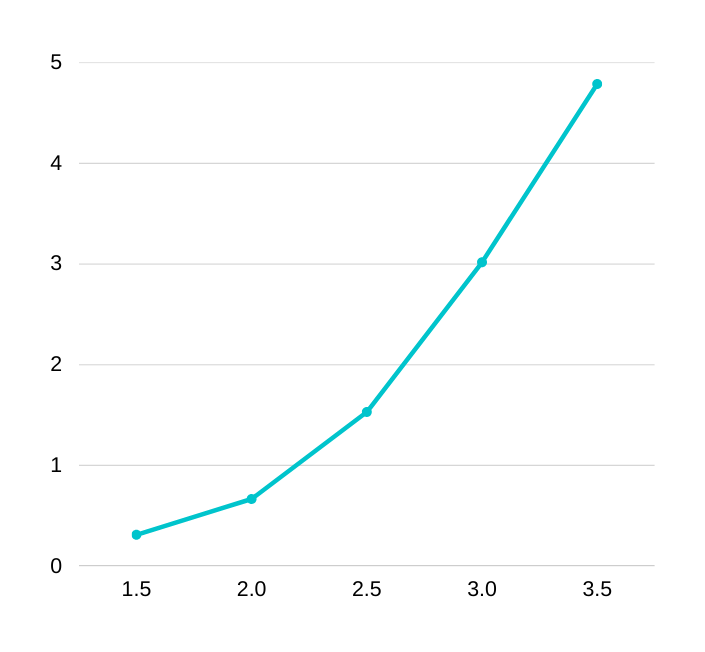

| Pipe size, nominal (in) | Second moment of area |

| 1.5 | \(\frac{\pi}{4} (0.9500^4 – 0.8050^4) =0.3099 \) |

| 2.0 | \(\frac{\pi}{4} (1.1875^4 – 1.0335^4) = 0.6657 \) |

| 2.5 | \(\frac{\pi}{4} (1.4375^4 – 1.2345^4) = 1.5296\) |

| 3.0 | \(\frac{\pi}{4} (1.7500^4 – 1.5340^4) =3.0172 \) |

| 3.5 | \(\frac{\pi}{4} (2.0000^4 – 1.7740^4) = 4.7877\) |

Interesting to note that the second moment of area grows exponentially relative to pipe diameter.

So we’re down to the brass tacks as they say.

| Pipe size, nominal (in) | Critical load, lb |

| 1.5 | \( \frac{\pi^2 * 30,000,000 * 0.3099 }{7784} = 11,848\) |

| 2.0 | \( \frac{\pi^2 * 30,000,000 * 0.6657 }{7784} = 25,452\) |

| 2.5 | \( \frac{\pi^2 * 30,000,000 * 1.5296 }{7784} = 58,483\) |

| 3,0 | \( \frac{\pi^2 * 30,000,000 * 3.0172 }{7784} = 115,361\) |

| 3.5 | \( \frac{\pi^2 * 30,000,000 * 4.7877 }{7784} =183,055\) |

Fun story. While making this post I got the modulus of elasticity for A36 steel wrong. I was collecting the data off the Internet and just about every site I checked listed the modules of elasticity for A36 steel as 30ksi instead of 30,000ksi Well with \(E=30ksi\) the critical load on our ~8 foot tall 1.5″ pipe column was coming out to be ~12 pounds. In other words, one could easily buckle it by pushing on it with their bare hands. That’s comedy right there.

It’s important to note that this critical load calculation makes one very critical assumption that the load being applied is exactly in line with the center axis of the column i.e. straight down. Because if the force is off in any direction then extra bending forces are being applied to the column which would reduce the buckling load.

Another thing to consider is the yield strength of the steel. If there is not enough metal then there is not enough strength in the column regardless what some fancy schmancy formula says. 3.5″ pipe for example, there’s no way that a column of any length will support 180klb. The mind reels at that scenario even if you could balance that weigh perfectly. The steel would simply squish out of the way like putty.